Hot forging in steel

Precision forming – High vertical integration

As one of the leading companies in forming technology, we produce over 40,000 tons of precision forgings such as flanges, valves, assemblies, and system solutions every year. Our range extends from development to production and logistics. With the help of state-of-the-art development and simulation tools, our engineers solve complex tasks.

The individual forming processes are coordinated using FEM simulations in such a way that the tools required for this are not subjected to excessive loads – for cost-effective production of the highest quality. With our range and the high level of vertical integration of our products, we supply a variety of industries, including the automotive industry, mechanical engineering, valve and pipeline construction, as well as road, mining, and tunnel construction.

Forging and Heat Treatment

We manufacture forgings weighing 0.5-15 kg on manual and fully automatic press lines. The following facilities are currently available to us for this purpose: MP2000, MP3150, AMP2000, AMP1600, AMP3150.

Even complex forgings can be shaped precisely, burr-free, and close to the final form. This saves resources, as further processing can be completely or partially omitted, and less material is used.

Thanks to optimizations in controlled cooling from forging heat, many products do not need to be reheated for heat treatment. This process offers great potential for CO2 savings. We are happy to advise you on the choice of materials and heat treatment processes.

Thanks to manual press lines, we can also offer small series of up to a few hundred pieces. We are happy to advise you on the choice of materials to save resources.

Mechanical Processing

We offer a wide range of machining processes: turning, milling, drilling, deburring. Crack testing, surface testing with BV technology, and cleaning are integrated into the processes. Our share of machined components is over 50 percent. For this purpose, we have a state-of-the-art machine park with 30 machining systems at our disposal – from various lathes to fully automatic assembly systems. This means we can offer you everything from a single source and special solutions for your projects.

Finishing and Assembly

All products are inspected and packaged according to customer requirements. In addition to visual inspection, we perform crack and eddy current testing. Quality testing takes place in our own measurement room and material laboratory. Here, experienced and qualified material testers check the quality of the products according to customer specifications and internal quality criteria. We also carry out further assembly of our products for you up to complete assemblies. Do not hesitate to contact us about your assembly projects.

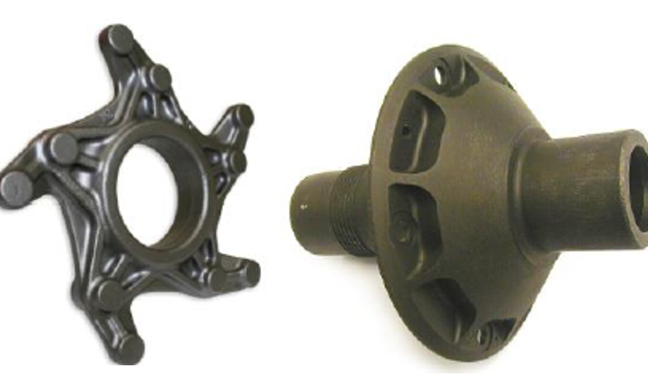

A Selection of Different Products

Our manufacturing parts are designed and produced for various purposes. We manufacture the right part for each project. Below you can see an overview of selected products.

Chassi

- Wheel bearings

Steering/Brakes

- Steering shafts

- Brake caliper lifters

Diesel injector

- Pump house

- Cylinder head

Engine

- Pistons

Differential shafts

- Precision-forged gears with finished teeth

E-mobility

- Stator-housings forged and machined

Industry - Tube/pin holders

- Flange housings

- Flanges

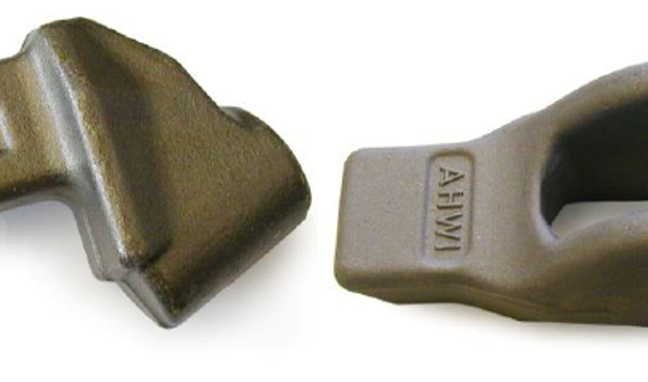

Industri - Mining & Tunnel

- Bit holders

Industri - Environmental articles

- Cylinder covers

- Terminal plates