From Idea to Finished Product…

Together with the customer, we develop the idea into a turnkey product.

With our expertise in manufacturing and modern tools, we aim to be at the forefront of customer support. Our development team is happy to help realize ideas.

Production

-

610g max. weight in polystyrene (PS)

-

Up to 2,500 kN clamping force

-

Up to 4 temperature control units per machine

-

Injection Molding of One or Multiple Components

-

Also with batching systems (gravimetric and volumetric)

-

And mixing nozzles for optimal color design

-

Insert / Outsert Technology

A Selection of Various Products

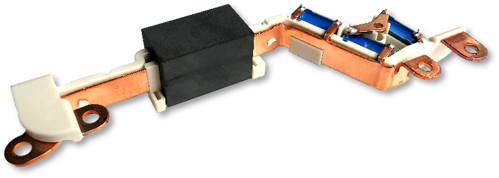

Bus bars - E-mobility

In-house Manufacturing of All Components

- Pressing and forming of copper and steel

- Plastic overmolding

- Assembly of ferrite cores, capacitors with soldering and ultrasonic welding

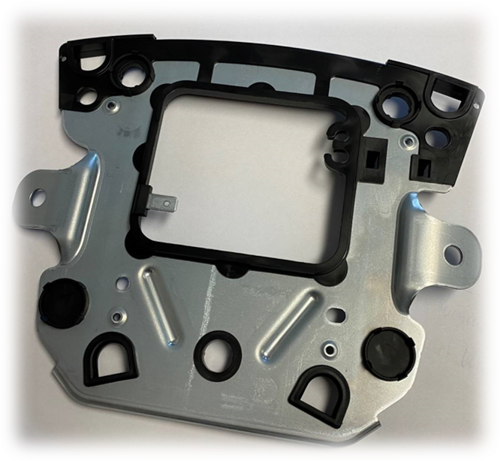

Steering wheel and column

In-house Manufacturing of All Components

- Pressing and forming of steel

- Plastic overmolding