Pressure vessels for transport and stationary storage. Made of steel and composite for working pressures of 200 bar and above.

We sell high-pressure vessels from leading manufacturers in Europe. Our pressure vessels typically handle pressures of 200 bar and above. They are mainly used for Bio/Natural gas and Hydrogen, but other types of gases are also common.

Our customers are primarily in the following sectors:

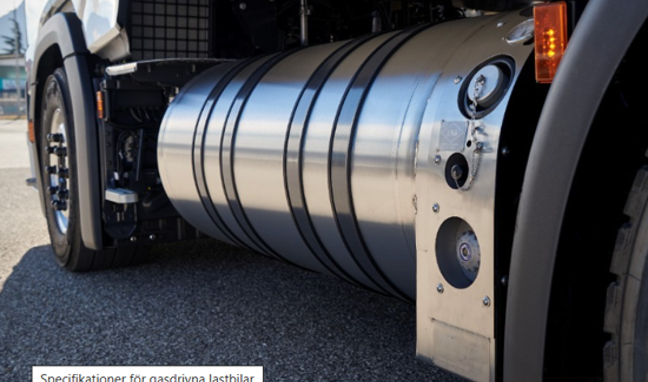

- Vehicles: such as trucks, buses, cars, trains, and also marine, off-highway with tractors, excavators, and earth-moving machinery for the propulsion of these vehicles.

- Fixed gas stations: Infrastructure and services for green energy gases with turnkey facilities where gas needs to be stored, including:

Fuel stations for various types of vehicles process, medical, agriculture, and food industries, etc.

- Mobile gas stations: Mobile units where gas needs to be transported between manufacturers and some form of stationary storage.

Steel (Type 1) or Composite (Type 4) Pressure Vessels

What Differentiates Them and Where Are They Used?

Where to Find Our Pressure Vessels?

High-precision products are custom-designed and manufactured by our experienced team for your specific purpose.

Inspection and Control – 10-Year Inspection

We perform 10-year inspections on steel pressure vessels.

Steel (Type 1) or Composite (Type 4) Pressure Vessels - What Differentiates Them?

There are essentially four different types of high-pressure vessels, from Type 1 to Type 4. Type 1 bottles, made of steel, are the most common, along with Type 4, which has a plastic inner liner and composite wrapping. Types 2 (steel + composite wrapping) and 3 (aluminum + composite wrapping) have not seen the same development.

The choice of bottle is primarily a combination of function/environment versus cost, along with safety and the desired gas pressure.

Steel Pressure Vessels (Type 1):

Advantages

- Lower price: Approximately four times cheaper than composite.

- Good resistance to external impacts: Such as shocks, sprays, and dirty environments.

Disadvantages

- High weight: Approximately four times heavier than steel.

Applications:

- Ideal for stationary applications due to their weight, such as industrial gas storage, water treatment, and chemical processing.

- The resistance to impact also makes it good for usage on heavy vehicle gastanks having the tanks underneath the vehicle.

Composite Pressure Vessels (Type 4):

Adavantage

- Weight: Significantly lighter than steel vessels, making them easier to handle and transport.(Aprox. 4 times lighter than steel-Type 1)

Disadvantages

- Higher Cost: Higher initial cost but lower total operational costs due to reduced maintenance and handling expenses.(Aprox 4 times a expensive than steel - Type 1)

- Sensitive to impacts: Such as shocks, sprays, and dirty environments.

Applications:

- Commonly used in vehicle applications such as vehicles (trucks, buses, trains), and for storing gases like hydrogen and natural gas.

Vehicles – Fixed Installations and Conversions to Gas Operation

Trucks/Buses for Biogas Operation

Vehicle Conversion to Gas

Gas Vehicles

Marine Vessels

More areas for pressure vessels

Food industry

Life science

Fire

Technical gas

Kontakta mig så berättar gärna jag mer om vårt erbjudande

Responsible Steel

ResponsibleSteel is the world's first global and independent standard for responsibly sourced and produced steel. The ResponsibleSteel standard provides a tool to evaluate and strengthen the sustainability efforts of our suppliers and principals through an ambitious industry-level framework that goes beyond compliance.

In combination with external audits and stakeholder engagement, ResponsibleSteel enhances the credibility and transparency of our sustainability efforts.

Currently, ResponsibleSteel has approximately 13% of the world's steel industry as members. There are over 80 ResponsibleSteel-certified facilities globally, producing over 130 million tons of steel annually

Our Requirements from Steelcenter

Most of the steel industry today has a very high awareness of responsible work in environmental and social commitments. Most, if not all, of our principals work diligently towards the goals they have set to simply be an attractive partner in the market.

Steelcenter is also extremely meticulous in choosing partners for our stainless steel products, who must have an active and progressive commitment to a secure future.

Today, much of the focus is on "Green Steel."