From Idea to Finished Product…

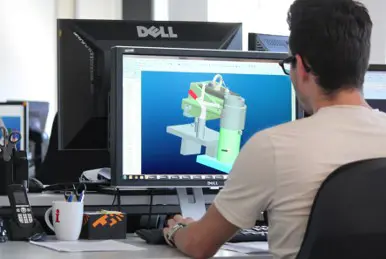

Together with the customer, we develop the idea into a turnkey product.

With our expertise in manufacturing and modern tools, we aim to be at the forefront of customer support. Our development team is happy to help realize ideas.

Production

In the beginning there was only sheet metal

- Production of complex stamping parts using progressive dies and transfer tools

- Press force 10 to 630 t and strip thicknesses up to 5 mm

- Processing of sheet metal of stainless steel, steel, brass, copper, bronze and aluminium

- Tooling:

- Maximum tool length 4.000 mm,

- Maximum strip width 800 mm

- Refinement is carried out to cooperation partners from the surrounding area

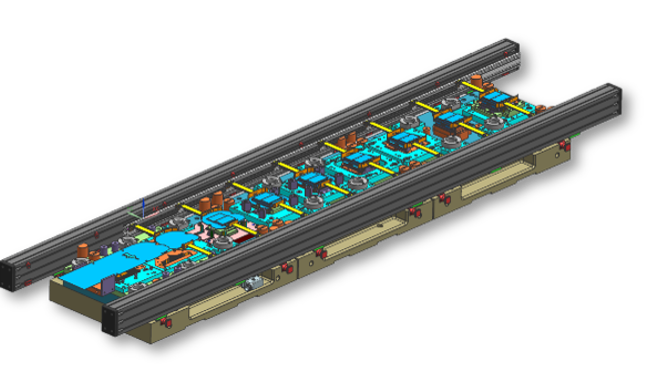

Tool and mold construction

Precision as key factor

-

Own construction and simulation with the help of state-of-the-art CAD/CAM technology

-

The range of services includes all types of stamping tools, bending tools, deep drawing tools, progressive dies, fixtures and operating equipment

-

Project planning software supports detailed scheduling and schedule control

A Selection of Various Products

Airbag modules

Complete internal productions

- Pressing och forming off cuper and steel

- Punching

- Klinch

- Welding

- Assembly

Steering column

All production steps made internally

- Fine punching and pressnng off all types off brackets

- Plastic processing

- Welding and assembly